Basic Introduction:

ATL series Rubber Injection Molding Machine is particularly designed for molding composite insulator. According to the product requirement and structure characteristics of the high voltage composite insulator (including hollow core insulator, tension and suspension insulator), the Rubber Injection Molding Machine is designed with clamping cylinder on the top and top mold upward moving mechanism. It is one of the masterpieces in the latest RIM innovation history. The Rubber Injection Molding Machine can help customers to realize high quality, high safety, and high production efficiency.

Features of the Rubber Injection Molding Machine:

Three step mold closing structure

Short clamping stroke; less sealing abrasion. Compared with the two-step clamping RIM of 1000mm opening stroke, the hydraulic oil consumption and sealing abrasion during clamping is only 1/180 and 1/200 respectively.

Bigger opening stroke can be selected, both big & long hollow insulator and suspension and tension insulator can be processed on the same machine.

Top mold upward moving mechanism

Rod/core placed to the fixed bottom mold, no movement, free of non-concentration/ shifting

Ergonomic operation height

Safe silicon feeding device

Rubber can be directly put into the loading gate which is 1.3m high from ground

Fully open loading gate, two hand actuated operation, light curtain protection(optional)

Photoelectric switch inspection and rubber shortage alarming function avoid screw dry run.

Parameters

Machine Model

|

Clamping Force

|

Opening Stroke

|

Injection Volume

|

Injection Pressure

|

Heating Plate Dim.

|

Total Power

|

|

KN

|

mm

|

c.c.

|

KGf/cm2

|

mm

|

KW

|

AT550L

|

5500

|

700-1000

|

13000

|

1260

|

630×1500

|

76

|

AT660L

|

6600

|

700-1000

|

18000

|

1260

|

650×1600

|

102

|

AT880L

|

8800

|

700-1500

|

25000

|

1260

|

1000×1600

|

105

|

AT1100L

|

11000

|

700-1500

|

25000

|

1260

|

800×2600

|

150

|

AT1800L

|

18000

|

1000-1500

|

50000

|

1260

|

1000×2600

|

210

|

Manufacturer of machines including tube filling, capping, cap pressing, neck sleeving, foil sealing, over wrapping and collating. Manufacturer of machines including tube filling, capping, cap pressing, neck sleeving, foil sealing, over wrapping and collating. Deals in new and used packaging and processing machines like induction cap sealing, bag and case sealing, shrink tunnels, form fill seal, blender and conveyors. Has product videos and finance options.

Production of composite tubes and products based on glass-carbon-aramid-epoxy. Insulating poles for maintenance of overhead power, telecommunication or traction overhead lines (de-icing, manipulation), current collectors for trolleybuses, insulating tubes and rods, components for ultra-light aeroplanes. [Czech republic] Design, product development and manufacture of high performance FW composite tubes for industrial applications, drive shafts, hydraulic and pneumatic cylinders. Marine tubes. Aaxial fibre filament laying process in carbon, glass or aramid. [IOW, UK] Manufactures a full line of boiler, heat exchanger, mechanical, and custom-engineered tubing products in both carbon and stainless steel.

Taiwan. Manufactures a range of shoe making machinery. Provides details of equipment available for producing vulcanized, sports, leather, and casual footware, as well as for processing NBR-PVC tubes and sheets equipment. Manufacturers of paper cone machines, tube for making textile cones, and spiral tube winding machines. Represent companies which make pipe corrugator machinery and downstream equipment for cutting, welding and winding corrugated pipe or convoluted tube. Maintain a list of used pipe corrugators for sale in North America.

Plastics machining solution for precision custom plastic parts out of sheet, rod and tube. Manufacturers of plastic spools, reels, dye tubes, bobbins, and cores. Volume distributor of plastic sheet, rod and tube, specializing in machined plastic parts.

Aluminum Plastic Laminated Tube

Aluminum Plastic Laminated Tube

Plastic Laminated Tube

Plastic Laminated Tube

Plastic Tube

Plastic Tube

Aluminum Tube

Aluminum Tube

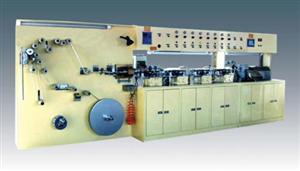

Automatic Laminated Tube Making Machine

Automatic Laminated Tube Making Machine

Automatic Shoulder Injecting Machine

Automatic Shoulder Injecting Machine

Aluminum Plastic Laminated Tube Machine

Aluminum Plastic Laminated Tube Machine

Injection Molding Machine

Injection Molding Machine

B-ZT-II Plastic Injection Forming Machine

B-ZT-II Plastic Injection Forming Machine

B-ZSN-II Plastic Injection Moulding Machine

B-ZSN-II Plastic Injection Moulding Machine